Holography has moved from the realm of futuristic science fiction into a practical tool that is transforming the field of non-destructive testing. This optical technique, which records and reconstructs the light scattered from an object, offers a unique way to detect flaws and structural issues without harming the material under inspection. By using holography, industries are finding new opportunities to ensure safety, maintain quality, and prolong the life span of critical components.

Principles of Holographic Testing

At its core, holography relies on capturing the interference pattern between a reference beam and the light reflected from the object being studied. When reconstructed, this pattern creates a three-dimensional image that reveals even minute deformations or changes on the surface. Because the method is so sensitive, it can identify issues invisible to the naked eye, making it especially valuable for complex structures in aerospace, automotive, and energy sectors. Engineers benefit from being able to examine detailed surface changes without needing to dismantle or alter the part. This reduces downtime, lowers inspection costs, and maintains the structural integrity of critical assets. The ability to visualize stress distribution also helps manufacturers improve design efficiency and extend the life cycle of their products.

Detecting Hidden Defects

One of holography’s strengths lies in its ability to uncover flaws beneath the surface. Subtle shifts in the holographic image can point to delamination, cracks, or early-stage fatigue. This is where its use becomes especially relevant to composite materials, which are widely used in modern engineering for their strength-to-weight ratio. While composites provide many advantages, they are also susceptible to hidden structural issues. A refined holographic setup can expose these weaknesses before they evolve into more severe damage. This makes holography an invaluable resource for ensuring long-term reliability in safety-critical applications. The growing interest in Disbond NDT has further demonstrated how non-destructive techniques continue to advance through optical innovations. By relying on holography, inspectors are better equipped to pinpoint subtle problems that might otherwise go unnoticed.

Benefits Across Industries

The versatility of holographic inspection makes it suitable for a wide range of applications. In aerospace, it helps guarantee the integrity of critical parts exposed to extreme stress. The automotive sector uses it to test components where even minor flaws could lead to performance issues. Energy companies apply it to evaluate turbines, pipelines, and other infrastructure that must withstand constant pressure. By reducing the need for destructive testing, holography saves both material and labor costs. The method also strengthens preventive maintenance strategies, ensuring components are repaired or replaced before failure occurs. This level of foresight reduces the risk of downtime while promoting long-term cost efficiency. Across industries, holography plays a pivotal role in balancing safety requirements with production efficiency.

Future Potential of Holography in Testing

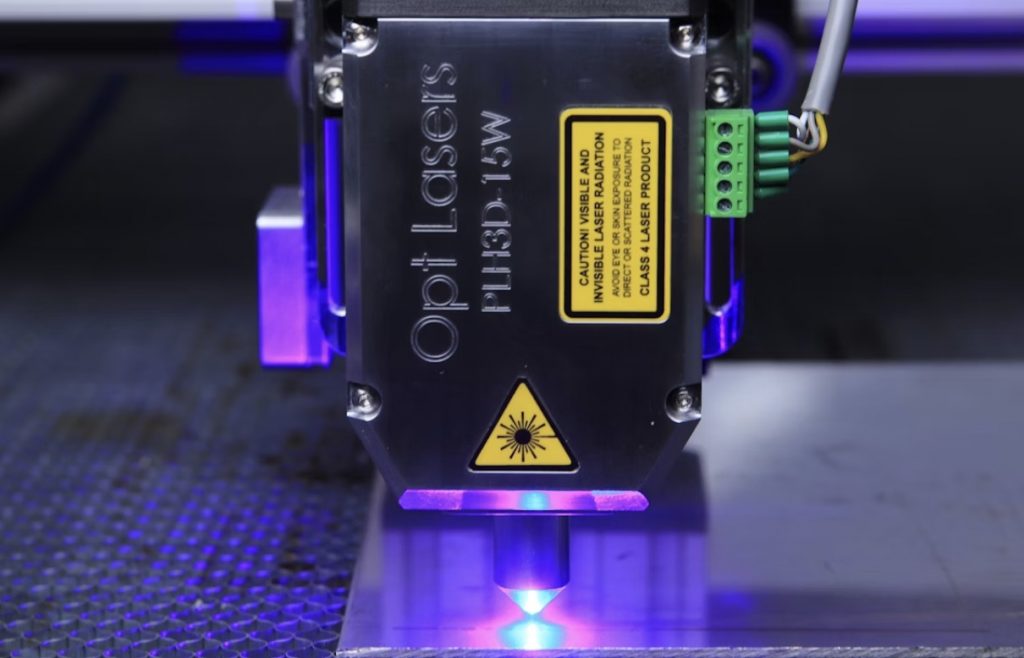

Although holography is already delivering significant results, its potential is far from fully realized. Advances in digital imaging, laser technology, and computational processing continue to expand what is possible. Portable holographic systems are beginning to emerge, offering flexibility for on-site inspections. As these tools become more accessible, industries of all sizes will be able to adopt them for routine testing. The ongoing integration of holography with automated systems and artificial intelligence is also shaping the next stage of development. By enhancing both accuracy and speed, these advancements are set to make holography one of the most reliable techniques available for non-destructive evaluation. The growing confidence in its capabilities points to a future where holography becomes a cornerstone of structural integrity management.

Holography’s adaptability ensures that it will not remain confined to specialized laboratories. With every refinement in the technology, new possibilities emerge for safer and more reliable evaluation. The path ahead suggests broader use in industries where reliability cannot be compromised. By combining precision with non-invasive examination, holography continues to strengthen the role of non-destructive testing as a foundation for modern engineering.

0 Comments