Gas-powered radiant heating systems have become a cornerstone technology in many industrial sectors, offering clean, efficient, and highly controllable heat transfer solutions. These systems use flameless infrared technology to deliver targeted heat directly to surfaces, reducing energy waste and improving production throughput. Whether in automotive painting, food processing, plastics manufacturing, or textile finishing, gas-powered radiant heating systems are redefining how heat is applied in industrial environments.

In this article, we explore the top five industries that benefit most from gas-powered radiant heating systems, highlighting real-world use cases and key advantages.

1. Automotive Painting and Coating

In the automotive industry, the quality and uniformity of surface coatings are critical. Paint curing processes must be precise and efficient to avoid defects such as cracking, peeling, or uneven coloration.

Gas-powered infrared panels are commonly used in:

- Basecoat and clearcoat drying, ensuring uniform drying without damaging sensitive substrates

- Powder coating lines, where rapid pre-gelling and curing are required

- Plastic parts finishing, offering low-temperature curing without deformation risks

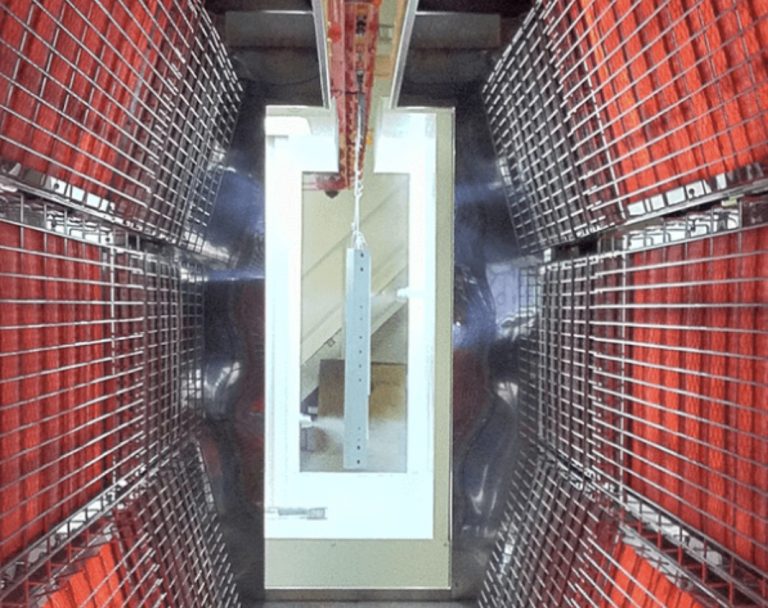

Technologies like Infracat® or Boostercat® panels provide consistent infrared radiation that penetrates coatings effectively while remaining safe for use in ATEX-classified zones due to their flameless design.

2. Food Processing and Thermal Treatment

Gas-powered radiant systems play a vital role in food production, where cleanliness, uniformity, and speed are essential.

Common applications:

- Drying coatings on baked goods and frozen foods

- Setting crusts on bakery products like bread or pizza

- Sterilizing and pre-heating food containers or packaging films

- Dehydration of snacks and cereals

Key benefits for the food industry:

- Hygienic flameless operation

- Fast response times

- Energy efficiency

- Compact integration into conveyor systems

These systems help maintain consistent product quality while meeting strict food safety and energy-efficiency standards.

3. Plastics and Composites Manufacturing

The plastics industry often deals with complex materials that require controlled heating to prevent warping, cracking, or uneven curing.

Gas-powered radiant heating systems are used for:

- Preheating molds in injection molding

- Post-molding stress relief treatments

- Surface activation for painting or printing

- Thermoforming and laminating sheets

These systems offer precise zoning and temperature control, ideal for complex parts and variable material thicknesses. The result is reduced cycle times, better part quality, and lower energy consumption compared to convection ovens.

4. Wood and MDF Surface Finishing

In the wood industry, curing coatings without scorching or deforming the material is a delicate task. Gas infrared systems provide a controlled, low-impact heat source that’s perfect for:

- Curing water-based and solvent-based varnishes

- Drying stains and sealers on furniture panels

- Achieving smooth, uniform finishes without overbaking

Because infrared radiation heats only the surface, these systems prevent thermal stress and allow for deep curing with minimal surface discoloration. Their modular design enables easy integration into modern finishing lines, improving both speed and consistency.

5. Textile and Technical Fabric Treatment

Textile manufacturers, especially those working with synthetic or technical fabrics, require contactless and uniform heating methods that are gentle yet effective.

Typical applications include:

- Drying inks from screen or digital printing

- Fixing flame-retardant or water-repellent coatings

- Heat-setting of synthetic fibers

- Pre-shrinking technical textiles

Advantages of gas-powered radiant systems:

- Flameless safety, essential for synthetic and combustible materials

- Even heat distribution, crucial for large fabric widths

- Modular scalability, from lab-scale units to full production lines

These advantages make infrared gas heating a top choice for improving product quality and process speed in textile operations.

Why These Systems Are Leading the Thermal Revolution

Gas-powered radiant heating systems are more than just heating devices—they are precision tools that enhance productivity, reduce operating costs, and meet the evolving demands of modern industry. Their flameless operation, energy efficiency, and versatile integration make them ideal for sectors where traditional heating methods fall short.

With manufacturers like Infragas at the forefront of innovation, the industrial world is rapidly embracing this technology for its proven performance and long-term value. Whether you’re optimizing a coating line, modernizing a food process, or upgrading a thermoforming plant, gas-powered radiant heating systems are a smart investment for the future.

0 Comments